The System

2AS - the modular waste collection system

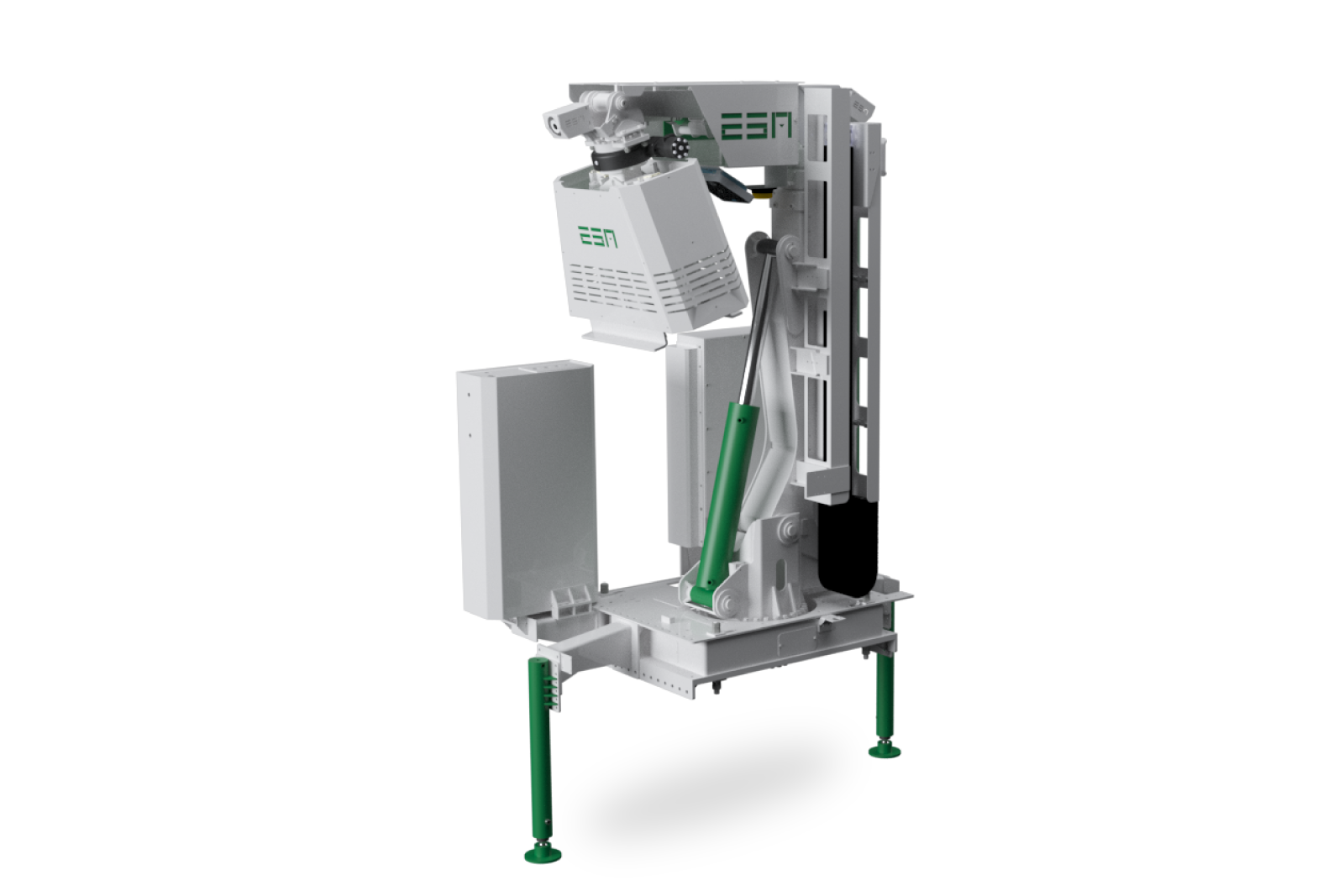

ROBOTIC

EQUIPMENT

2AS bilateral equipment for hooking and lifting of containers, provided with automatic system and control devices for management by single operator.

WASTE COMPACTORS

CONTAINER WASHERS AND

OPEN TOP CONTAINERS

complementary stationary or roll-off equipment, suitable to every chassis for waste management and logistics.

SOLAR POWERED

COMPACTORS

ecological waste compactors powered by photovoltaic energy, suitable for temporary events and markets, movable by 2AS system.

CHASSIS

the system can be integrated on the most diffused types of 2, 2+1, 3 and 4 axle chassis on the market.

CONTAINERS

the system is suitable for lifting above ground containers in recycled HDPE, underground containers and all the containers provided with Kinshofer hook.

Bilateral equipment 2AS for hooking and lifting of containers of different kinds and volumes, equipped with an automatic system and control devices for management by single operator.

7

CAMERAS

the seven IP cameras allow total control of the operations through the touch and scroll monitor placed inside the cockpit

UHF CONTAINER

RECOGNITION SYSTEM

the UHF tag on the container, read by the antenna placed on the robotic equipment, allows the system to identify the data and the operating status of the container itself

SELF-LEVELLING

the equipment is provided with an automatic levelling system, capable of safely managing any operation, even with long distance hooking (*see load diagram)

LASER

giude

the robotic equipment movement system is assisted, through the software, from the latest generation laser pointing system

INTEGRATED

WEIGHING SYSTEM

the weighing system integrated in the robotic arm allows the immediate control of the quantity of waste took in charge

CLAMP

FOR HOOKING

the current configuration of the clamp allows the hooking of all the containers provided with different lengths of Kinshofer hook

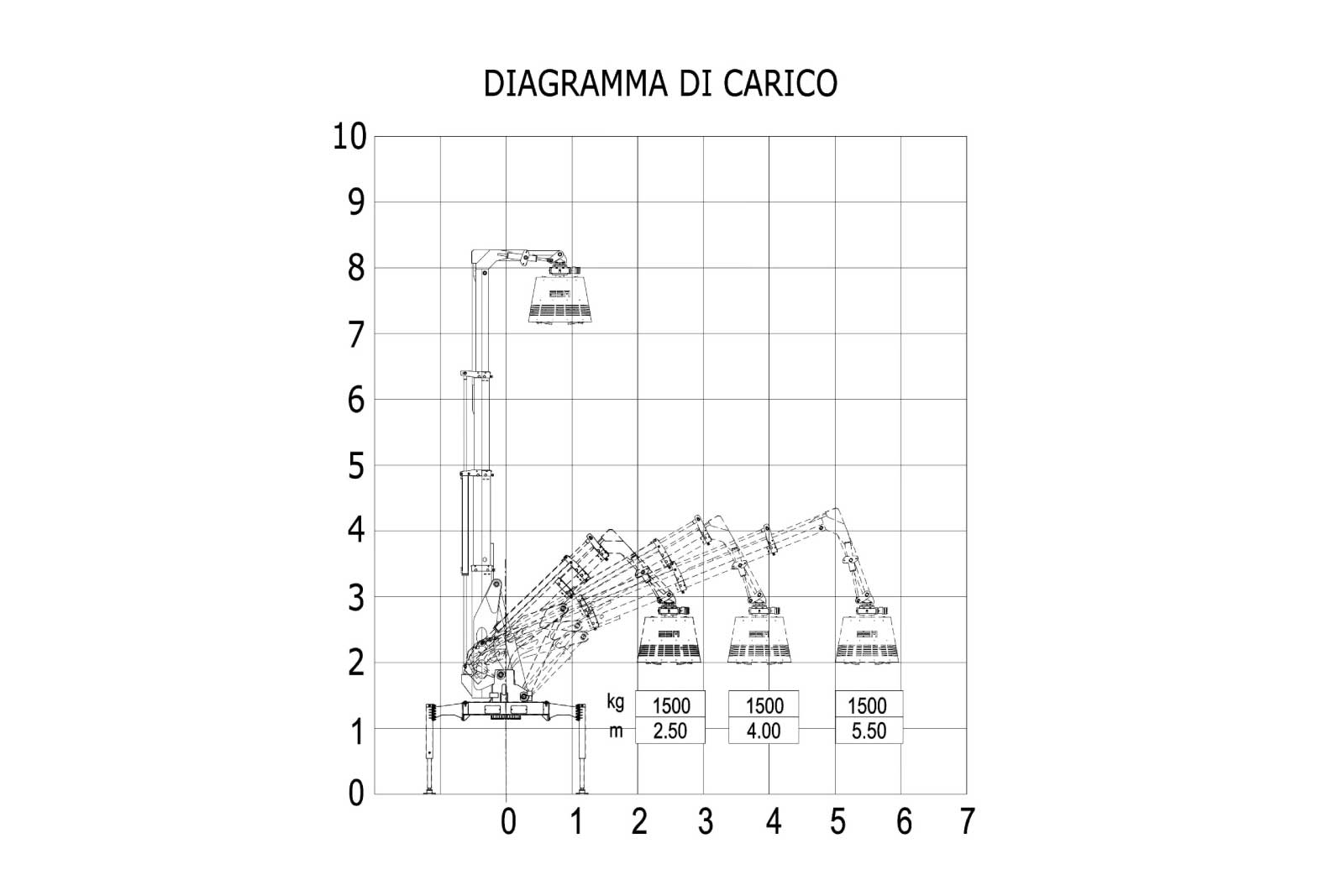

LOAD

DIAGRAM

the lifting capacity up to 2,500 Kg and the extension capacity up to 5,5 m allow the hooking also in presence of obstacles place in front of the container

The robotic crane can be installed on every chassis on the market, also methane powered. Moreover, 2AS allows to fit compactors, containers washers and open top containers to meet all the operational needs. The current configuration of the clamp allows the hooking of all the containers provided with different lengths of Kinshofer hook.

One vehicle for different operations.

• 2006/42/CE - machinery directives

• directive on electromagnetic compatibility

• 2014/35/UE - “low voltage” directive

• ISO 4306 2010 - lifting devices

ROLL-OFF AND

STATIONARY SYSTEM

the robotic equipment can be installed on every chassis on the market; 2AS can also be installed on both roll-off and stationary systems in combination with compactors, containers washers and open top containers.

NOZZLE CONTAINERS

WASHING SYSTEM

the nozzles with high water jet pressure, also hot, allow a better wash and sanitization of surfaces and they extend the life of the containers themselves in the absence of mechanical rubbing

Advantages

2AS - the waste collection system of the future

65” COMPLETE

OPERATING CYCLE

reduction of the time needed to complete the entire operating cycle to give greater availability to perform other activities related to the service with consequent less pollution.

SINGLE MAN

OPERATED

greater efficiency in execution of the service with minimal use of staff compared to classic collection work

BILATERAL

COLLECTION

greater freedom in the positioning of the road containers

DOUBLE ROW

LIFTING

lifting capacity in double row and overcoming obstacles placed in front of the container

PAYLOAD

9.500 Kg

the higher payload, given by the lightness of the equipment, allows a greater autonomy of conferment, reducing the trips to empty the load; lower CO2 emissions

*with 3 axle chassis, 26 Ton

and stationary compactor

WORKERS

HEALTH

the ease of managing all the work from the cockpit avoids he onset of chronic diseases in the long term; moreover the worker is less likely to be exposed to bacteria and polluting agents. This guarantees a better quality of the work

THE BEST

ROUTE

the filling level detection systems and those for sending the parameters of exercise placed on the containers allow to program the daily path from time to time, avoiding unnecessary emptying and increasing the organizational efficiency of the collection

LOWER

COSTS

by type of waste collected, work area, distance of the house from the container and longevity of the equipment, it is possible to save on the costs of the collection compared to the same work with traditional methods

MODULAR

SYSTEMS

2AS robotic equipment can be equipped on every chassis on the market and allows the installation of waste compactors, containers washers and open top containers. The current configuration of the clamp allows the hooking of every container provided with different lengths of Kinshofer hook.A single vehicle for multiple operations.

Technology and R&D

2AS - IoT applied to the world of waste

Our devices can provide the following services:

CONTROLLED

ACCESS

to improve separate collection services, the manager could incentivize citizen virtuous behavior through the registration of conferment data and users could easily access the service via SMARTPHONE or CARD

SENDING OF OPERATING

PARAMETERS

the various sensors placed on the container detect the filling level, communicating to the system when this needs to be emptied and report any anomalies in real time

THE BEST

ROUTE

by sending of the operating parameters, it is possible to program the daily path from time to time, avoiding unnecessary emptying and increasing the organizational efficiency of the collection

24/7 REMOTE ASSISTANCE

AND CONTROL

to maintain the efficiency and effectiveness of the equipment over time, ESA offers a constant upgrade of the management software and a 24/7 remote assistance service. Therefore, the software is continuously updated, and the ordinary maintenance interventions decrease significantly

CONTAINER

RECOGNITION SYSTEM

the UHF tag placed on the container allows the system to recognize the content of the container and the operating status of it, while GPS identifies its position

THE IDEAL MODEL

FOR EVERY CITY

a system of infrastructures and technologies always interconnected allows a smart and sustainable management of the services offered to citizens of modern smart cities